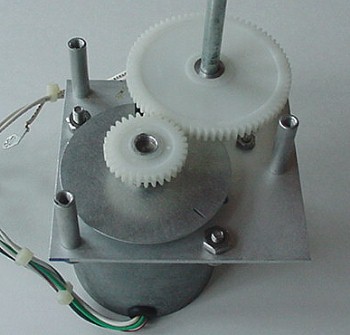

A single-shaft stepper motor and two non-metal gears make a simple assembly that is perfectly matched to a 30 degree (11 position) rotary switch. The stepper motor is fixed to a 3 in x 3.25 in x 0.063" aluminum plate, which is attached to the panel with three 1" threaded aluminum spacers. The gears and limit sense wheel (the circular disk underneath the smaller gear) fit in the 1" gap between the panel and aluminum plate, so that the entire assembly adds only 1 inch of depth to the stepper motor.

The gears are 32 pitch. The small gear is 24 teeth, 0.75" diameter, and the large gear is 72 teeth, 2.25" diameter. The combination results in a reduction ration of 1:3, which reduces each step of a common 1.8 deg/step stepper motor to 0.6 degrees. Fifty steps will turn the rotary switch exactly 30 degrees, or one position. Note that a panel bearing (not shown) is required to support the front shaft of the large gear.

.

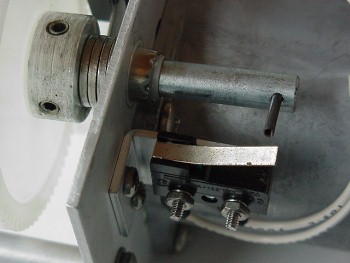

At the left is a closeup of the limit wheel (note the small slot). If you want to duplicate this idea, you should attach the wheel to the large gear, rather than the small gear shown here. In this setup, the wheel is fixed to the hub of the small gear with small screws. However, the simpler (though admittedly less elegant) approach that I used is to fit a rubber grommet into the wheel and simply slide the grommet onto the shaft. Once the wheel is aligned properly, a dab of silicone caulk keeps the grommet from moving. (If you really want to get down and dirty, you can use a soup can lid for a wheel, and drill a small hole for the light beam.) Optical interrupters are available at Jameco, All Electronics, Digikey, etc. and cost only a dollor or two.

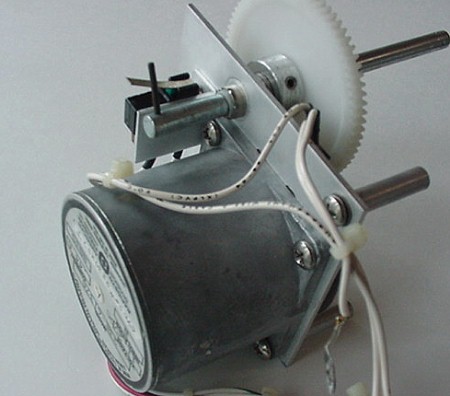

As shown at the right, a mechanical switch can be used to sense the end of rotation of the switch or variable capacitor. The electrical requirement is merely to ground a wire to the controller when the capacitor or switch is at its "home" position. In an optical detector, the wire is grounded when a phototransistor detects a light beam from the slit in the sense wheel. In the setup at the right, a microswitch is closed by a pin attached to the shaft of the gear.

At the left is another view of the E.T.O stepper/gear mechanism. A good source of gears (and almost all other hardware) is McMaster-Carr (http://www.mcmaster.com/). Check page 921 of their catalog, or search for "Spur Gears & Racks." You can buy them in stainless steel, aluminum, or acetal (non-metallic) plastic. New gears are rather expensive, but they pop up frequently in surplus catalogs and can often be scavenged from other equipment.